Description

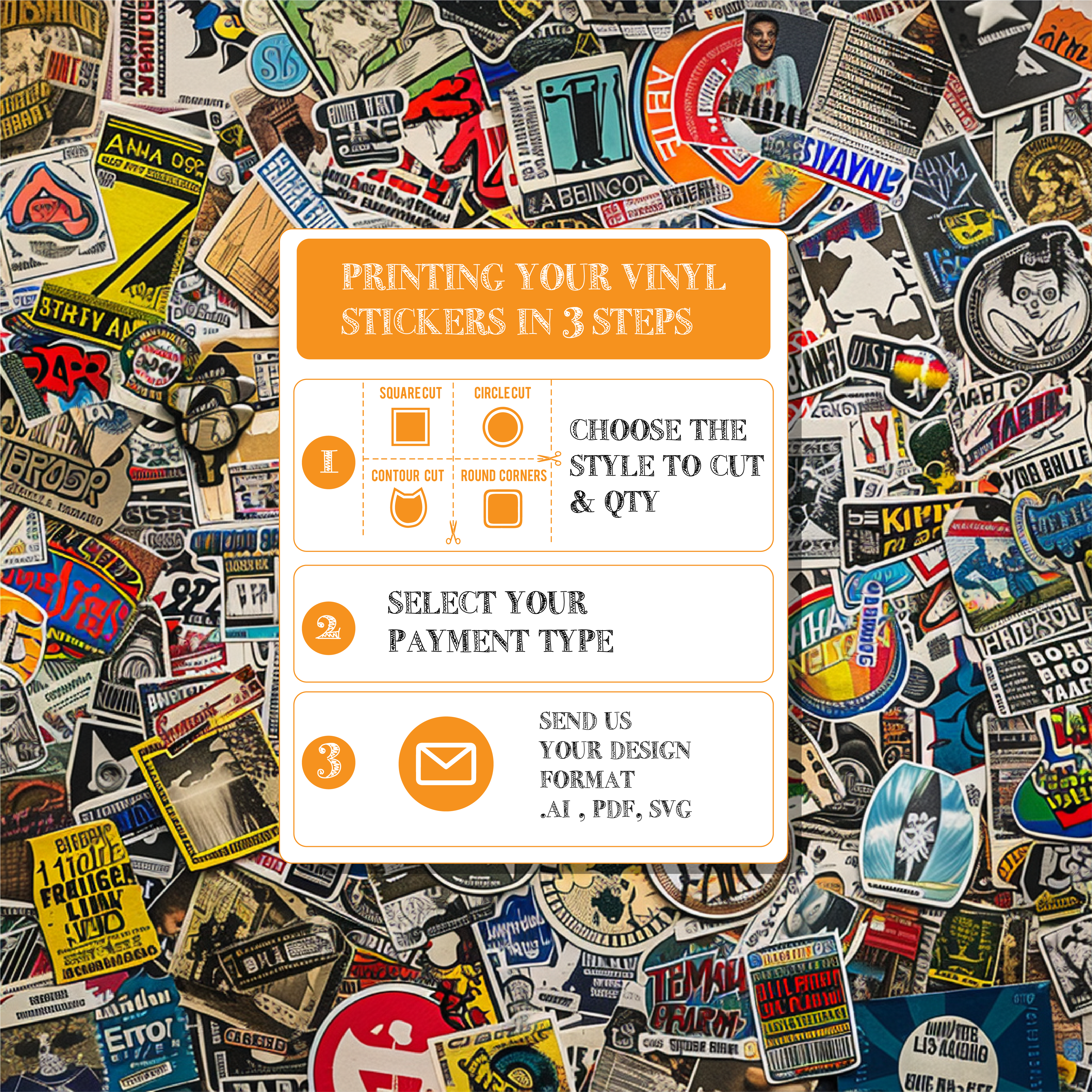

STEP 1: CHOOSE THE STYLE OF CUT FOR YOUR STICKERS:

- CONTOUR

- SQUARE

- CIRCLE

- ROUND CORNERS

STEP 2: CHOOSE THE QUANTITY, SIZE AND UPLOAD YOUR GOOD RESOLUTION DESIGN ON .PDF, .AI, .SVG, PNG FORMATS.

STEP 3: CHOOSE THE METHOD OF PAYMENT.

WHAT DOES WEATHER RESISTANT MEAN?

The main difference between laminated stickers (weather resistant) and non-laminated stickers lies in their durability, appearance, and protection against wear and tear. Here’s a breakdown of the key differences:

Durability:

Laminated Stickers: Laminated stickers are generally more durable because they have an additional layer of protective coating (laminate) applied over the sticker material. This laminate can be made from various materials such as vinyl, polyester, or polypropylene. The laminate acts as a barrier against moisture, UV rays, and physical abrasion, which helps to prolong the life of the sticker.

Non-Laminated Stickers: Non-laminated stickers do not have this extra protective layer. As a result, they are typically more susceptible to fading, scratching, and damage from exposure to the elements.

Appearance:

Laminated Stickers: Laminated stickers often have a glossy finish due to the clear laminate layer. This glossy finish can enhance the colours of the sticker and give it a more professional look.

Non-Laminated Stickers: Non-laminated stickers may have a matte or semi-gloss finish depending on the material used. They can appear more basic in comparison to laminated stickers.

Protection:

Laminated Stickers: The laminate layer provides excellent protection against water, oil, dirt, and UV rays, which helps to prevent the sticker from fading, discoloration, or peeling over time.

Non-Laminated Stickers: Without a protective laminate layer, non-laminated stickers are more prone to damage from moisture, sunlight, and physical handling.

Reviews

There are no reviews yet.